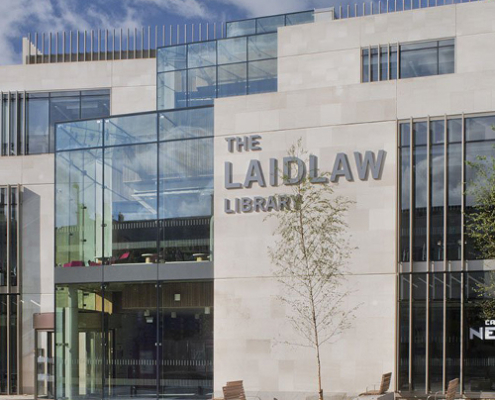

School of Chemical and Process Engineering

- Work began: September 2015

- Work completed: September 2017

- Cost: £38M

- Contractors: Galliford Try

Brief: Full refurbishment of levels 3 to 5, refurbished laboratories, new Postgraduate research space, refurbished lecture theatres and a new 24/7 IT Cluster.

Latest News

More Information

The project aims to incorporate new state of the art facilities into the Engineering building to enable ambitious growth in academic activity.

During the two year phase of work the building will remain occupied with users being re-located as and when required. In the first 12 months work will focus on levels 3-5 followed by 12 months involving works around the remaining areas in multiple phases.

The new contemporary environment will create open and flexible laboratory spaces and breakout and informal meeting areas.

Laboratory spaces

As part of the University’s ongoing investment in nuclear fission research, the School of Chemical and Process Engineering will be opening a suite of three purpose built laboratories for research using radioactive materials. The laboratories will have space for pilot scale rigs, bench top chemical experiments and high specification analytic equipment and researchers will be able to use uranium and thorium in their experiments. The planned opening of the new laboratories is April 2016.

Photonics Laboratory

Transformation to the building will also see the creation of a new photonics laboratory. The laboratory will host £1.3M ultrafast laser plasma implantation equipment supported by an EPSRC strategic equipment grant.

The new facility will enable advanced functional materials engineering with ultrafast laser plasma manufacturing, laser plasma diagnostics for materials characterisation and process control, nonlinear optics, optical waveguide fabrication and characterisation, photonic integrated circuits engineering, microlaser engineering and, optical sensors for health and environment.

The equipment will not only allow research but will also enable two of the University’s spinout companies Glucosense Diagnostics and Ultramatis Ltd to use the facilities for commercial applications.

A unique laser plasma manufacturing section of the laboratory will feature high spec femtosecond laser with a materials processing vacuum chamber. The plans also incorporate options for future expansion to multiple process chambers/lasers, clean working area for materials preparation/storage and precision glass cutting and polishing. The characterisation section will have optical tables for waveguide laser and amplifier experiments, biosensors, mid-IR waveguide devices and nonlinear optics. This is partly supported by the £2.5M EPSRC manufacturing of functional materials project.

The laboratory will support the research of academics in the area of photonics research.